Quality by Design

By Mark Land, M.S., RAC-US, AAHP

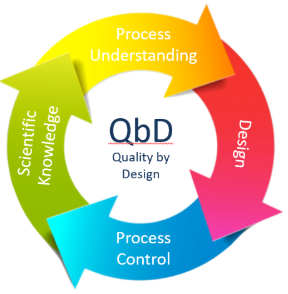

Quality by Design (QbD) is a systematic approach to product and process development that begins with predefined objectives and emphasizes product and process understanding and control, based on sound science and quality risk management. Unlike traditional methods that rely heavily on testing at the end of the process, QbD builds quality into the product from the start by identifying critical quality attributes (CQAs) and understanding the process parameters that influence them. This proactive approach leads to a robust, consistent process, improved product quality, and continuous improvement.

- Defined Objectives: Defined objectives are critical to the success of any QbD project. Start with clear goals, focusing on the desired product quality attributes. Product Quality Attributes (PQA) should be patient or consumer focused.

- Product and Process Understanding: Understanding your process is essential to establishing Critical Process Parameters (CPPs). To establish CPPs investigate and understand the relationship between process inputs, the manufacturing process, and the final product’s quality.

- Quality Risk Management: Understanding your process and establishing CPPs allows you to identify, assess, and control potential risks to product quality throughout the development lifecycle.

- Control Strategy: Your control strategy using CPPs allows you to implement a strategy that ensures the process consistently produces the product within acceptable limits, using in-process testing allows for continuous monitoring.

- Continuous Improvement: Gather data from manufacturing to gain further insight into the process and identify opportunities for ongoing improvement.

Quality by Design can be applied across the supply chain — from vendor qualification, and materials selection to testing and process validation. Check out our three articles (An Overview Application of a Quality-by-Design Model for Hahnemannian Dilutions, Supplier Audits, and FDA Issues Warning Letters Alleging Unapproved New Drug Status and CGMP Non-Compliance) in AAHP’s October issue that discuss vendor qualification and QbD principles applied to the process of making homeopathic dilutions to illustrate the range of applications of Quality by Design principles.

Here are a few guidance documents that more fully elaborate the principles of designing quality into the product and process:

ICH Q8(R2) Pharmaceutical Development (2009)

ICH Q9(R1) Quality Risk Management (2023)

ICH Q10 Pharmaceutical Quality System (2009)